Electronics manufacturing service (EMS) providers are many times incorrectly chosen as the default choice for a contract manufacturing partner.

When multiple manufacturers are working on a product that includes electronic components, the printed circuit board assembly (PCBA) manufacturer frequently serves as the de facto coordinator and assembler of all components from other manufacturers. At MME group, our experience tells us that businesses benefit when they question this inefficient and all-too-common practice.

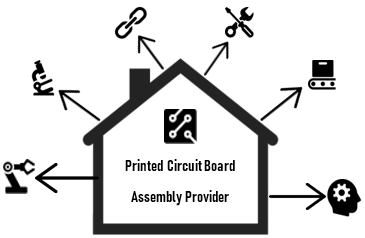

PCBA professionals, while immensely skilled, do not typically focus on the full spectrum of manufacturing and assembly capabilities necessary to coordinate multiple manufacturing partners. Instead, they focus on their primary function: Printed circuit board assembly (PCBA) services, and everything else is outsourced. As a result, the product development and launch process takes longer than it should. Natural revisions and product changes that take place during any development process, instead of being handled quickly, lead to communication and logistical delays.

Outsourcing project components:

A Common and Often Problematic Configuration

Many businesses use this manufacturing partner configuration. However, this can lead to long turnaround times for even minor adjustments, among other challenges.

The new default for a contract manufacturing partner should be one that is more vertically integrated, and has a depth of expertise beyond building circuit boards. A full-service manufacturer can quickly identify and act on component adjustments to incorporate a circuit board, but a board manufacturer must frequently communicate with numerous component manufacturers in order to make similar adjustments. The resulting inefficiencies can be costly and increase the time it takes to bring a product to market.

Why Business Initially Use That Configuration

When a business selects a PCBA manufacturer as the lead contract manufacturer on a project, the choice typically revolves around software updates, firmware updates, and embedded system analyses and management practices during development and into final programming and testing. It is assumed that because a mechanical manufacturer does not build PCBA boards they will not be able to provide support. It is likewise assumed that the PCBA manufacturer of choice will elect not to be cooperative in helping with those types of issues.

That is often not the case.

At MME group, for example, we are a mechanical manufacturer with PCBA partners who bring expertise and resources to bear. These PCBA professionals are able to focus on what they do best. This is preferable when compared to their providing assembly, logistics, and other services that fall outside of their expertise.

In truth, many PCBA board manufacturers prefer to focus on their core strengths – making circuit boards and providing electronic engineering support – instead of serving as the full-service contract manufacturer on a project. However, many businesses initially fail to understand this and instead focus on enlisting PCBA manufacturers as their full-service provider.

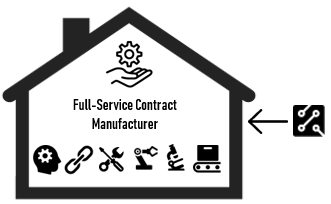

An Improved Manufacturing Partner Configuration

With a fuller breadth of skills to make component adjustments in house, a full-service contract manufacturer can streamline communication, bring about cost savings, provide important design insights, and bring a product to market most quickly. This, in short, utilizes PCBA manufacturers to their full potential and allows each member of the team to focus on core strengths.

Project components in-house:

End-to-End Contract Manufacturing Solutions

Businesses turn to MME group for end-to-end, vertically integrated contract manufacturing solutions. Our depth of experience and ability to coordinate between multiple partners allows us to tackle unique challenges – making us a leading organization for businesses seeking a true manufacturing partnership.

—

Read more about our contract manufacturing capabilities: https://www.mmegroupinc.com/contract-manufacturing/