Our ISO certifications and ITAR & FDA registration represent our commitment to excellence

Quality is not confined to one department or team at MME group. Quality is instilled at every level of the company and is the cornerstone of all that we do. We hold ourselves accountable for product outcomes; accountability defines our culture.

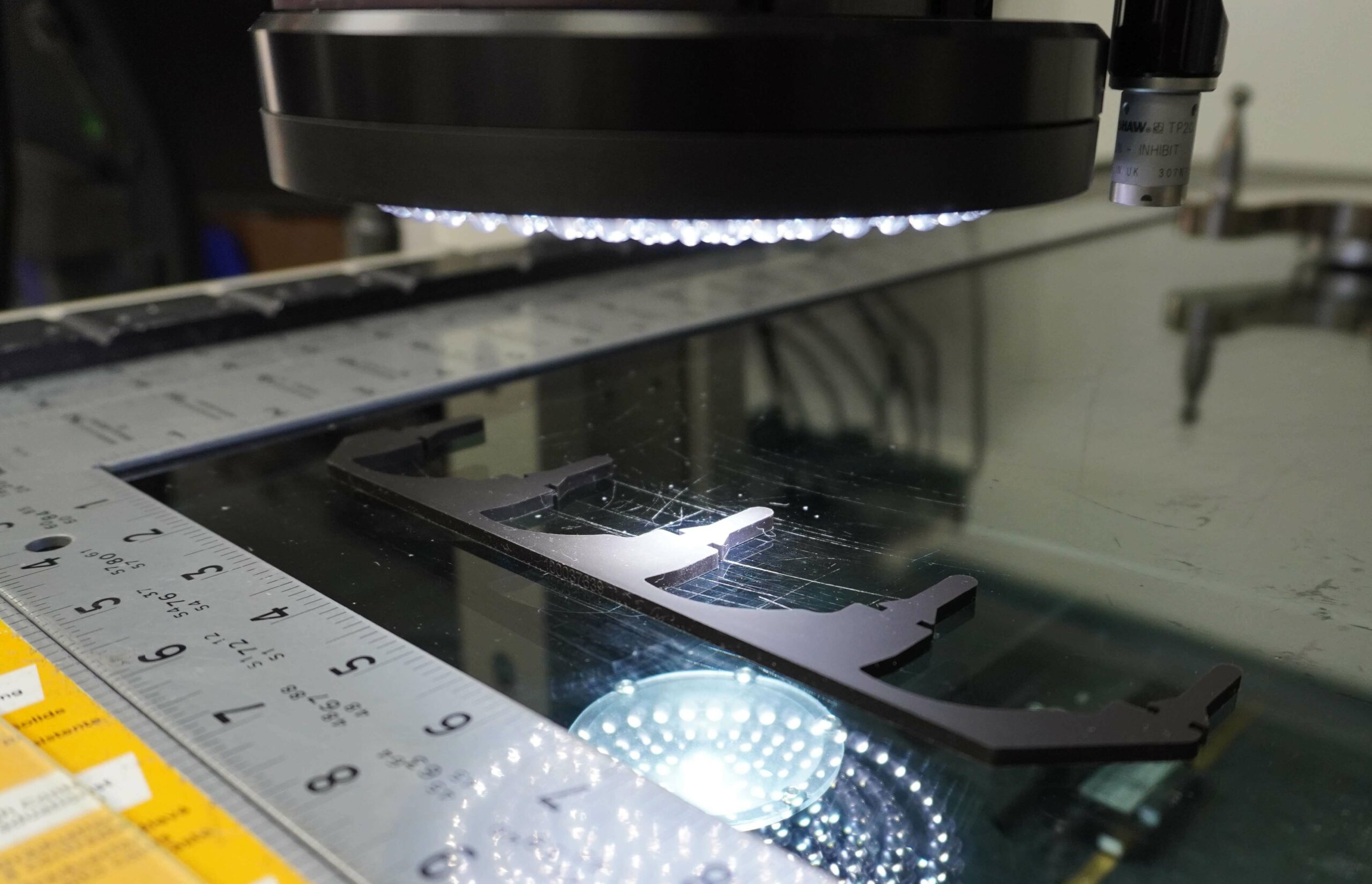

Quality Control

You dictate quality measurement criteria. We work with the end result in mind and complete advanced planning and risk analysis. Along with your quality controls, we apply a tiered quality system appropriately designed to your program needs. We support standard qualification to full FDA validation.

Quality Management Systems

We are ISO 13485:2016, which is a specialized certification for medical component manufacturing, and are ITAR and FDA registered for adhering to U.S. export laws for government projects.

"Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution; it represents the wise choice of many alternatives."

-William A. Foster

Our Certifications & Registrations

Collaborative Product Qualification

- IQ, OQ, PQ Qualification and Validation

- Automotive PAPP

- Control Plan

- FMEA / PFMEA

- SPC Analysis

- Cpk / Ppk Analysis

- FAI

- Supplier Quality Management

- Incoming Inspection

- Melt Flow Index Testing

- Pull Force Testing

- Moisture Testing

- In Process Inspection

- In Process Inspection Fixtures

- Non-destructive thickness checks

- Gage R&R

- Lot Traceability