Objective

MME group was hired by client to develop and manufacture a single use transfusion cassette used for the collection of blood components, i.e. platelets, plasmas, red cells and mono -nuclear cells.

Solution

- Created aggressive timeline to meet launch date.

- Collaborated with customer during DFMA process.

Results

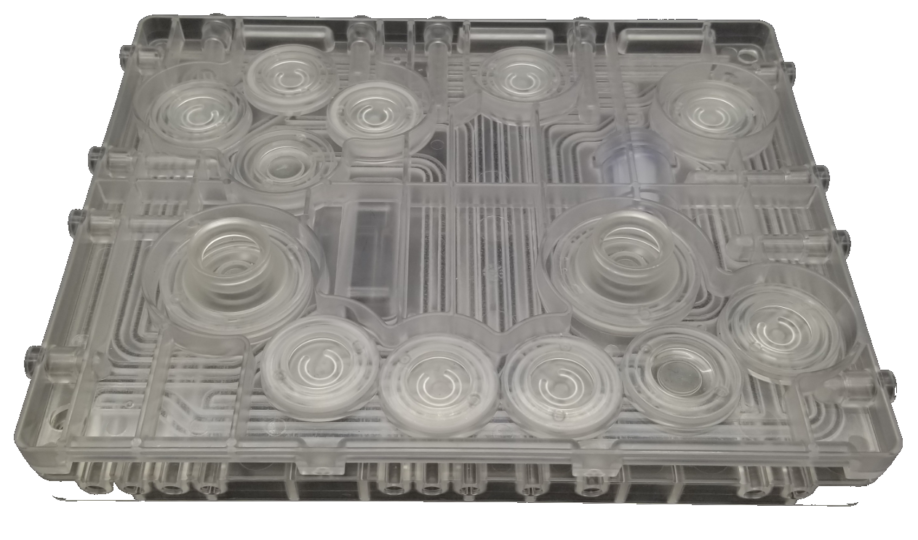

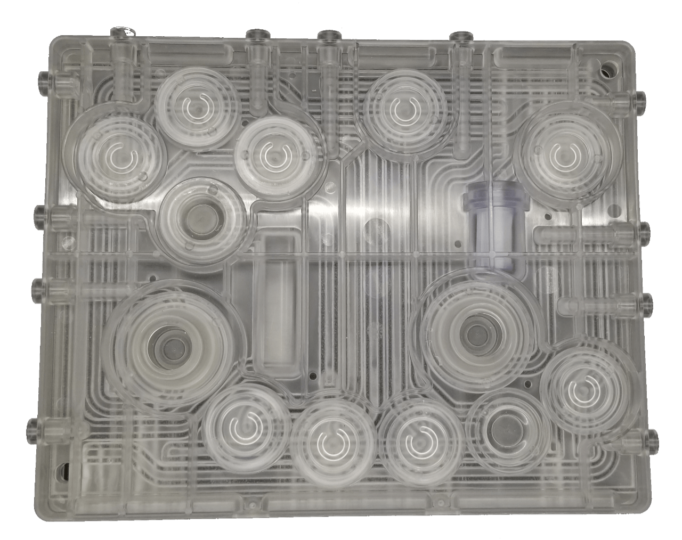

- The top and bottom cassettes, as well as 13 silicone diaphragms, which help regulate the fluid flow through the system, are molded in one of our class 8 clean rooms.

- Once molded, the parts enter the nearby assembly line and the silicone diaphragms are welded onto the top cassette.

- A small filter is placed in between the top and bottom cassettes, which then get hot plate welded together to form a hermetic seal.